- Transformer Aluminium Strip

- Color Coated Aluminium Strip

- Aluminium Jacketing Insulation Coil

- PCB Entry Aluminium Board Strip

- Aluminum Plastic Composite Strip

- Aluminium Slit Strip

- Window Shutter Aluminium Strip

- Aluminium Corner Strip

- Aluminium Air Duct Strip

- Car License Aluminium Strip

- Heat Exchange Aluminium Strip

NEWS

INFORMATIONTel:

86 17344894490 Location : Home/Aluminum Plate/ 5052 5083 5754 5454 5005 5A02 5A05 Aluminium Circle

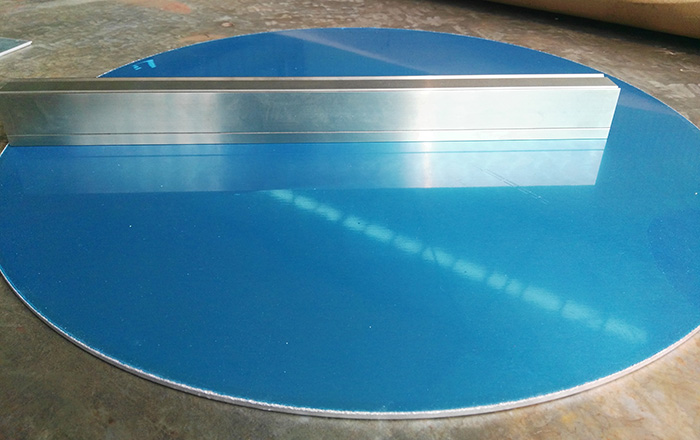

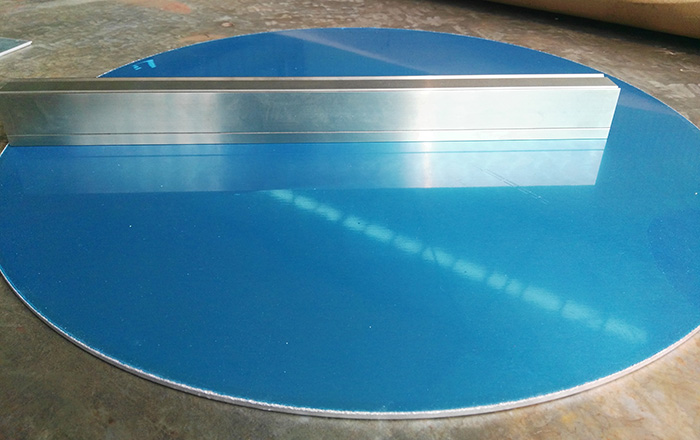

5052 5083 5754 5454 5005 5A02 5A05 Aluminium Circle

Last Updated :2023/07/03

5052 5083 5754 5454 5005 5A02 5A05 Aluminium Circle

Signi aluminium is professional aluminium circles manufacturer in China, the aluminium circles because of its DDQ--deep drawing quality and spinning quality, hard anodizing quality, they are widely used for making cookware, cooking utensils, non-stick cookware etc. The spinning quality deep drawing quality aluminim circles norally include alloy A3003, ally A3004, alloy A1200, alloy A1100, alloy A1070, alloy A1060, alloy A1050, and normally in temper O, H12 and H14,O temper aluminium circles normally is used for making cookware body, H12 and H14 temper aluminium circles normally used for making cookware cover, H14 temper circles sometimes used to make cookware bottom. Our A1050 A1060 A1070 A1200 A1100 A3003 A3004 aluminum circles are hot rolled quality, fine grain, after anodizing the surface no looper line, very bright and excellent pearl color surface.

Signi Aluminium manufactures alloy 5052 5083 5754 5454 5005 5A02 5A05 aluminium circle with with higher strength and excellent in forming and corrosion resistance that can be subject to further treatment by the following methods: deep drawing, spinning,etc.

Alloy: 5052 5083 5754 5454 5005 5A02 5A05

Temper: O, H12, H14,H16,H18,H22,H24,H26,H32,H34

Thickness: 0.4~150mm

Diameter: 80~1200mm

Surface:Mill finish

Diameter List

Mechanical Properties

Properties

Spec: BS EN 485-2:2008

Sheet - 0.2 - 6.3mm Thick

Spec: BS EN 485-2:2008

Plate - 6.3mm to 80mm

Spec: BS EN 485-2:2008

Plate - 80mm to 120mm

Chemical Properties

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ga | V | Ti | Other | Min.A1 |

|

5052 5083 5754 5454 5005 5A02 5A05 |

0.25 | 0.40 | 0.10 | 0.10 | 2.2-2.8 | 0.15-0.35 | - | 0.10 | - | - | - | 0.15 | Remainder |

| Section | Alloy | Characteristics | Application | |

| 5000 series |

AA5A02 AA5A05 AA5005 AA5052 AA5754 AA5454 AA5083 |

Have higher strength than 3000series and excellent in forming and corrosion resistance |

Spare parts, Rocket bottom,Pressure Vessel,Oil tanker cover,Cover in outdoor,etc. |

|

Diameter List

| ≧20 | ≧140 | ≧170 | ≧200 | ≧250 | ≧300 | ≧400 | ≧500 | ≧600 | ≧700 | ≧800 |

| 20 | 140 | 170 | 200 | 250 | 300 | 400 | 500 | 600 | 700 | 800 |

| 25 | 141 | 172 | 203 | 252 | 305 | 405 | 505 | 610 | 705 | 810 |

| 93 | 142 | 173 | 205 | 254 | 310 | 410 | 510 | 615 | 710 | 838 |

| 100 | 143 | 175 | 210 | 255 | 312 | 420 | 515 | 619 | 720 | 890 |

| 105 | 144 | 176 | 211 | 258 | 315 | 425 | 520 | 630 | 730 | 902 |

| 109 | 145 | 177 | 212 | 260 | 320 | 430 | 525 | 635 | 740 | 945 |

| 110 | 147 | 178 | 215 | 267 | 325 | 435 | 530 | 645 | 760 | 960 |

| 112 | 149 | 180 | 216 | 268 | 330 | 440 | 540 | 650 | 770 | 1000 |

| 115 | 150 | 181 | 217 | 270 | 335 | 445 | 545 | 655 | 780 | 1150 |

| 118 | 153 | 182 | 218 | 272 | 340 | 450 | 550 | 665 | 1200 | |

| 120 | 154 | 183 | 220 | 274 | 345 | 455 | 560 | 670 | ||

| 121 | 155 | 184 | 221 | 275 | 350 | 460 | 565 | 680 | ||

| 122 | 157 | 185 | 222 | 277 | 355 | 465 | 570 | 690 | ||

| 123 | 158 | 188 | 225 | 278 | 360 | 470 | 575 | |||

| 124 | 160 | 190 | 226 | 280 | 364 | 475 | 580 | |||

| 127 | 161 | 192 | 230 | 282 | 368 | 480 | 585 | |||

| 128 | 162 | 193 | 233 | 285 | 370 | 485 | ||||

| 129 | 163 | 195 | 235 | 290 | 375 | 490 | ||||

| 130 | 164 | 198 | 237 | 292 | 380 | 495 | ||||

| 132 | 165 | 238 | 293 | 385 | ||||||

| 133 | 166 | 240 | 295 | 390 | ||||||

| 134 | 167 | 242 | 395 | |||||||

| 135 | 168 | 245 | ||||||||

| 136 | 169 | 249 | ||||||||

| 137 | ||||||||||

| 138 | ||||||||||

| 139 |

Mechanical Properties

| TEMPER | THICKNESS(mm) | TENSILE STRENGTH | ELONGATION% |

| HO | 0.36-6 | 60-100 | ≥ 20 |

| H12 | 0.5-6 | 70-120 | ≥ 4 |

| H14 | 0.5-6 | 85-120 | ≥ 2 |

Properties

| Physical Property | Value |

| Density | 265 g/cm3 |

| Melting Point | 570 C |

| Thermal Expansion | 25 x10^-6 /K |

| Modulus of Elasticity | 72 GPa |

| Thermal Conductivity | 121 W/m.K |

| Electrical Resistivity | 0.058 x10^-6 .m |

Spec: BS EN 485-2:2008

Sheet - 0.2 - 6.3mm Thick

| Mechanical Property | Value |

| Proof Stress | 125 Min MPa |

| Tensile Strength | 275 - 350 MPa |

| Hardness Brinell | 75 HB |

Spec: BS EN 485-2:2008

Plate - 6.3mm to 80mm

| Mechanical Property | Value |

| Proof Stress | 115 Min MPa |

| Tensile Strength | 270 - 345 MPa |

| Hardness Brinell | 75 HB |

Spec: BS EN 485-2:2008

Plate - 80mm to 120mm

| Mechanical Property | Value |

| Proof Stress | 110 Min MPa |

| Tensile Strength | 260 Min MPa |

| Hardness Brinell | 70 HB |

| Elongation A | 12 Min % |

5052 5083 5754 5454 5005 5A02 5A05 Aluminium Alloy circle Features :

1.Alloy 5052 5083 5754 5454 5005 5A02 5A05 aluminium circle with higher strength and excellent in forming and

corrosion resistance

2.Wide range of selection on circles' size including customized shape and size.

3. Excellent reflectivity, good for Polishing;

4.Excellent deep drawing and spinning quality.

5.Good anodized quality, suitable for hard anodizing and enameling;

6.Clean surface and smooth edge, hot rolled quality, fine grains and after deep drawing no looper lines;

7.Excellent pearl color anodizing.

8.RoHS and REACH compliance

9.Well-Protected Packing

5052 5083 5754 5454 5005 5A02 5A05 Aluminium Alloy circle Intended uses :

making Spare parts, Rocket bottom,Pressure Vessel,Oil tanker cover,Cover in outdoor,etc.

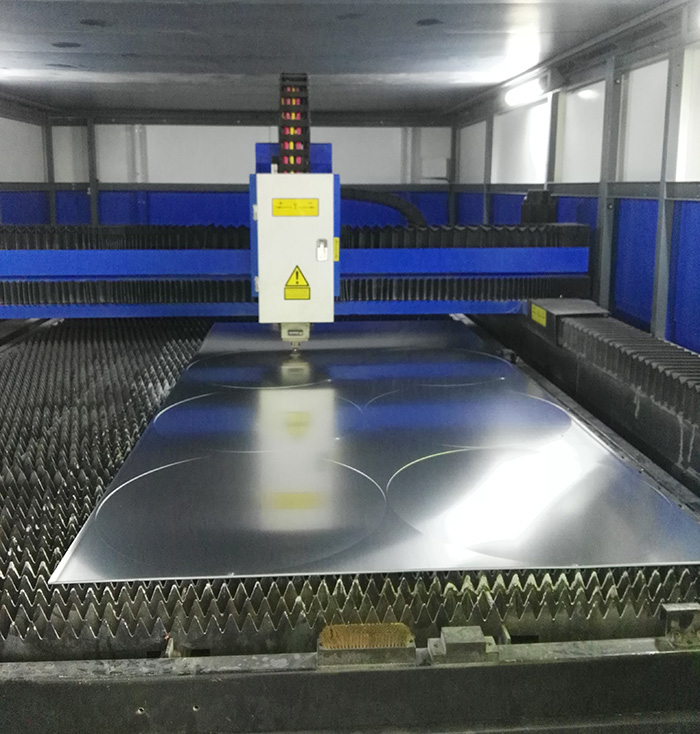

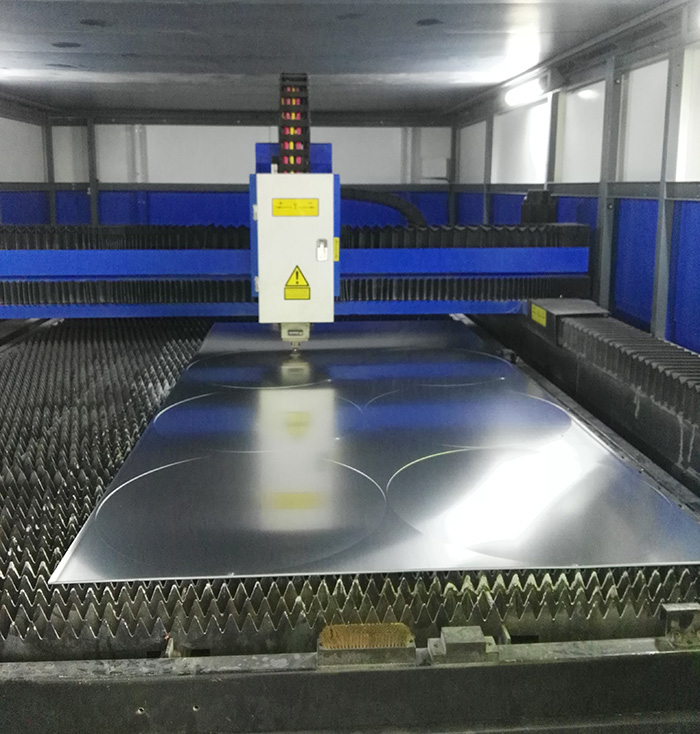

5052 5083 5754 5454 5005 5A02 5A05 Aluminium circle production line :

1.Prepare the master alloys

2.Melting furnace :put the alloys into the melting furnance

3.D.C.cast aluminum ingot:To made the mother ingot

4.Mill the aluminum ingot:to make the surface and side smooth

5.Heating furnnace

6.Hot rolling mill:made the mother coil

7.Colding rolling mill:the mother coil was rolled as the thickness you want to buy

8.Punching process:become the size what you want

9.Annealing furnace:change the temper

10.Final inspection

11.Packing:wooden case or wooden pallet

12.Delivery

5052 5083 5754 5454 5005 5A02 5A05 Aluminium circle package :

1.Put the driers side the aluminium circle , keep the products dry and clean.

2.Use the clean plastic paper , packing the aluminium circle , keep good sealing.

3.Use the snakeskin paper , packing the surface of the plastic paper , keep good sealing.

4.Next , There are two ways of packaging :

One way is wooden pallet packaging , using the crusty paper packing the surface ;

Another way is wooden case packaging , using the wooden case packing the surface.

5.Final , lay the steel belt on the wooden box 's surface , keep the wooden box fastness and secure.

5052 5083 5754 5454 5005 5A02 5A05 Aluminum circle advantages :

1.Good quality of deep drawing aluminium circle , and can maintain semi-specular finish with a

65% minium total reflectivity after bright dip and anodize.

2.Henan Signi speciality is in deep drawing quality . Grain size is tightly controlled to minimize

the "orange peel effect " , The "orange peel effect" is a rough surface,like the surface of an orange peel,

which often occurs after deep drawing. Signi tightly controls the chemistry and heat treating to

maximize the elongation that allow the materials to stretch more.

3.Henan Signi is a major aluminium circle producer of bottom plates , Signi has been producing impact bonded bottom plates in high volumnes for more than 10 years.